Air, Nitrox, and Trimix Fills

American Dive Zone offers air fills and mixed gas fills for scuba divers. We have the ability to blend any enriched air nitrox mix for your diving. Air tanks are filled while you wait and nitrox and trimix fills are done within 24 hours.

Annual Regulator Inspection

Regulators are life support equipment and should be well maintained to reduce risk while diving. ADZ offers regulator inspection & adjustment services to ensure regulators work as they should. Our service techs complete a full checkout on regulators during an inspection and will tune them to manufacturers’ standards.

Regulator Rebuild

Regulators should be rebuilt every other year to maintain their reliability. During a regulator rebuild, we carefully dismantle your regulator, meticulously clean each component, and reconstruct it per the manufacturer’s specifications using original manufacturer parts. We then bench test the regulator and conduct a 10-minute immersion test to detect any leaks.

We are an authorized SCUBAPRO dealer and can rebuild any SCUBAPRO regulators.

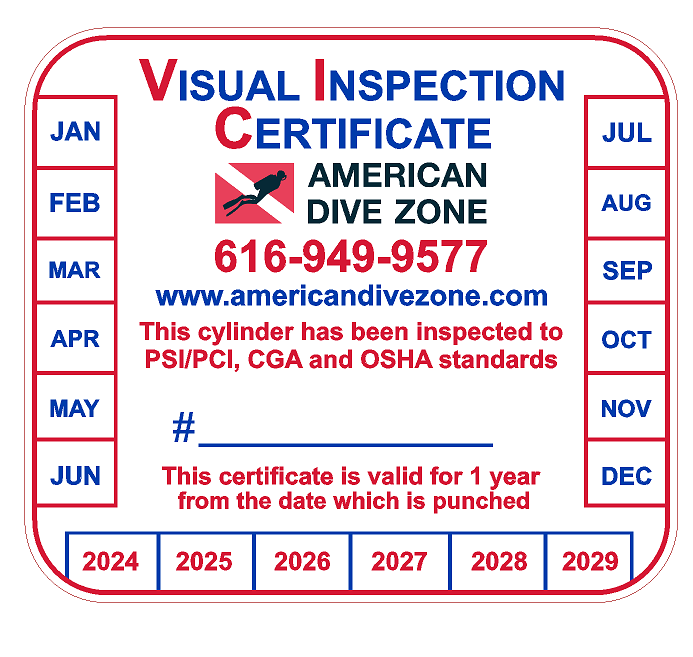

Scuba Tank Visual Inspection

During a visual inspection, we (1) check the exterior of the tank for signs of impact damage, (2) inspect the threads for damage, and (3) inspect the interior of the tank for signs of corrosion and damage. We also check the tank’s valve for damage. Assuming everything checks out, we will put a new o-ring on the valve and add our visual inspection certificate to the tank.

Scuba tanks are high-pressure vessels, and any structural failure can lead to catastrophic consequences, including explosions or rapid air loss underwater. As such, tanks must be inspected every 12 months to ensure they are safe to use.

Hydrostatic Testing of Scuba Tanks

Hydrostatic testing is a critical safety procedure for scuba tanks that must be done every five years.

Hydrostatic testing involves pressurizing the tank with water to a level significantly higher than its normal operating pressure. This test ensures that the tank can safely contain the pressure of the gas it’s designed to hold during diving activities. Over time, scuba tanks can develop weaknesses, such as metal fatigue, corrosion, or material defects. Hydrostatic testing helps detect these weaknesses by subjecting the tank to high pressure, which can reveal any potential structural issues that could lead to failure during use.

We provide hydrostatic testing for scuba tanks through a reputable local partner.

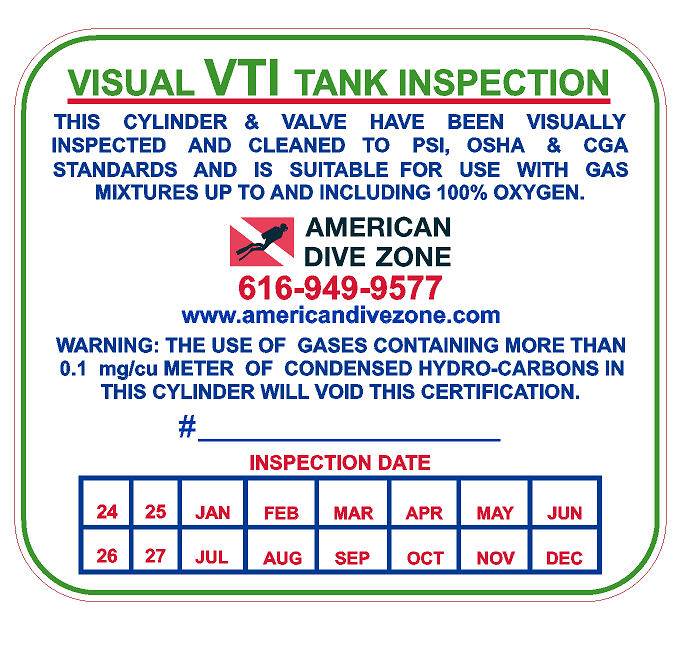

Scuba Tank O2 Cleaning

O2 cleaning a scuba diving tank is a critical process that ensure the tank is safe to use with high concentrations of oxygen. O2 cleaning removes any contaminants that could react with oxygen under high pressure.

At American Dive Zone, we have a 5-step process for O2 cleaning scuba diving tanks to make them safe for high O2 concentrations.

All nitrox tanks filled at American Dive Zone are required to be O2 cleaned after visual inspections and hydrostatic testing.

BCD Inspection and Adjustment

American Dive Zone offers BCD inspection and adjustment services to ensure your equipment is working as it should. During our BCD inspection, we check the low-pressure inflator functionality, check the bladder for leaks, and replace any worn buckles or components.